The second of two major disclosed issues about the Audi, was a “massive” power steering leak, and that the belt had been removed from the power steering pump in order to protect it from damage by running dry. As with with everything so far, this turned out to be a gross understatement.

First, on this car, it is not just a “power steering” pump. That would be far too pedestrian for this Tutonic Wuderauto. The same pump also supplies hydraulic pressure to the power brake booster. On some Euro-market cars, they took it a step further, and it also ran the self-leveling rear suspension. Regardless, it’s a critical component, running a several important systems, with a lot a plumbing.

To get started, I figured I’d top up the fluid reservoir and see if any fluid fell out anywhere. This car, of course, doesn’t take any run of the mill power-steering fluid which you can find on the shelf of any auto parts store for a couple bucks per bottle. No sir, not this car. Pentosin CHF 7.1 is the specified fluid.

CHF 7.1 is an older mineral oil based formulation, and unsurprisingly has gotten hard to find. There’s a lot of mixed information out there on:

1) If it’s safe to mix it with the newer CHF 11s synthetic stuff

2) If a system originally spec’ed for 7.1 can even take 11s without exploding

3) When Audi actually made the switch over from one to the other.

Taking a best guess after reading too much, I decided to just go with the older mineral oil based fluid. Then I went to buy some.

Back 15 years ago when I needed to buy some of this stuff, it was kinda pricey, but holy smokes, current prices are over $50 / quart! The system needs about a quart to completely fill. Fine, except I have a massive leak. To avoid pouring $50 directly on the ground, I shopped around. I found that Beck/Arnley makes a compatible fluid for like $12 /quart — perfect.

Having secured three quarts, I dropped some number of ounces in the system and observed. I suspected the leak was somewhere down where the lines met the steering rack, as things looked pretty wet in that area. I put a shop towel down there to see if it caught any drips. I didn’t see anything at first, so left and came back to it later. What I found later, was that all the fluid was gone from the reservoir and my towel was soaked — okay getting closer!

Can you see where the lines are? Yeah neither can I, but they’re somewhere back above the vicinity of the blue shop towel.

I repeated this exercise a couple of times; armed with lights and a mirror I was able to determine that indeed, the pressure line to the rack had a pretty decent drip. Access to lines on the rack are TIGHT, but moving the reservoir out of the way and with enough finagling I was able to get a socket on it and removed the banjo bolt.

A split washer. There’s no way that’ll hold anything, clearly.

This system calls for a solid zinc crush washer. Eagle eyed, readers might note, that the above washer is neither solid, not zinc. So, some shoddy previous work had reared it’s ugly head here. No problem, I’ll just grab one from the parts store.

Back in the day, if I needed a crush washer in some size, I didn’t really need to know or care about the particular size. I would take the old washer to the autoparts store, and pick one out of a box that matched for about $0.25. In the modern autoparts world, which has been completely destroyed by MBAs and consolidation, there’s nothing in the store that doesn’t have a separate sku to be scanned, tracked and dropped from inventory because it’s in the bottom 20% of things sold in a given year. In other words, there are no longer boxes full of assorted washers for $0.25 each.

Given this horrifying retail situation, I ended up digging through Audi Parts diagrams, to find a VAG part number, then attempt to cross-reference it in various systems. In the end, I found the washers I need and it only cost me like $5 and 3 hours of research. With the hose reinstalled with fresh washers it was time to put more Magical German Mineral Oil (Deutscher zauber öl) in the system.

I filled the reservoir and let it sit overnight. The next day, there were no drips! I figured I’d attempt to bleed the system. I did so by spinning the pump pulley by hand. It felt a little lose, but the fluid level dropped indicating we were circulating fluid into the entire system. Wait a minute, this pump pulley is REALLY lose — it shouldn’t wiggle up and down…Oh, look fluid is now pouring out from behind the pulley. Sigh.

In the best case this meant that the main pump seal was shot — I guess the previous owners didn’t remove the belt “to protect the pump” in time and in fact burned up the seal. I hoped the damage was limited to the pump seal.

A little dismayed, but still undeterred, I found a pump rebuild kit, which contained about about 2 dozen o-rings and the pump shaft seal. Once the kit came in the mail (we’re like 2-3 weeks into dealing with this pump at this point) I removed the pump, disassembled it and….oops. Junk.

This thing was just destroyed. So, now I had to make an attempt at sourcing a new pump. NO parts house had a rebuilt unit. Worse, there are three different versions of the pump and each version of the pump required a different set of banjo bolts to attach the hydraulic lines. The bolts, of course, are no long available at any price from anywhere. I reached out to the local Audi groups and someone had a “recently” rebuild unit which matched mine on the shelf — $200. Fine.

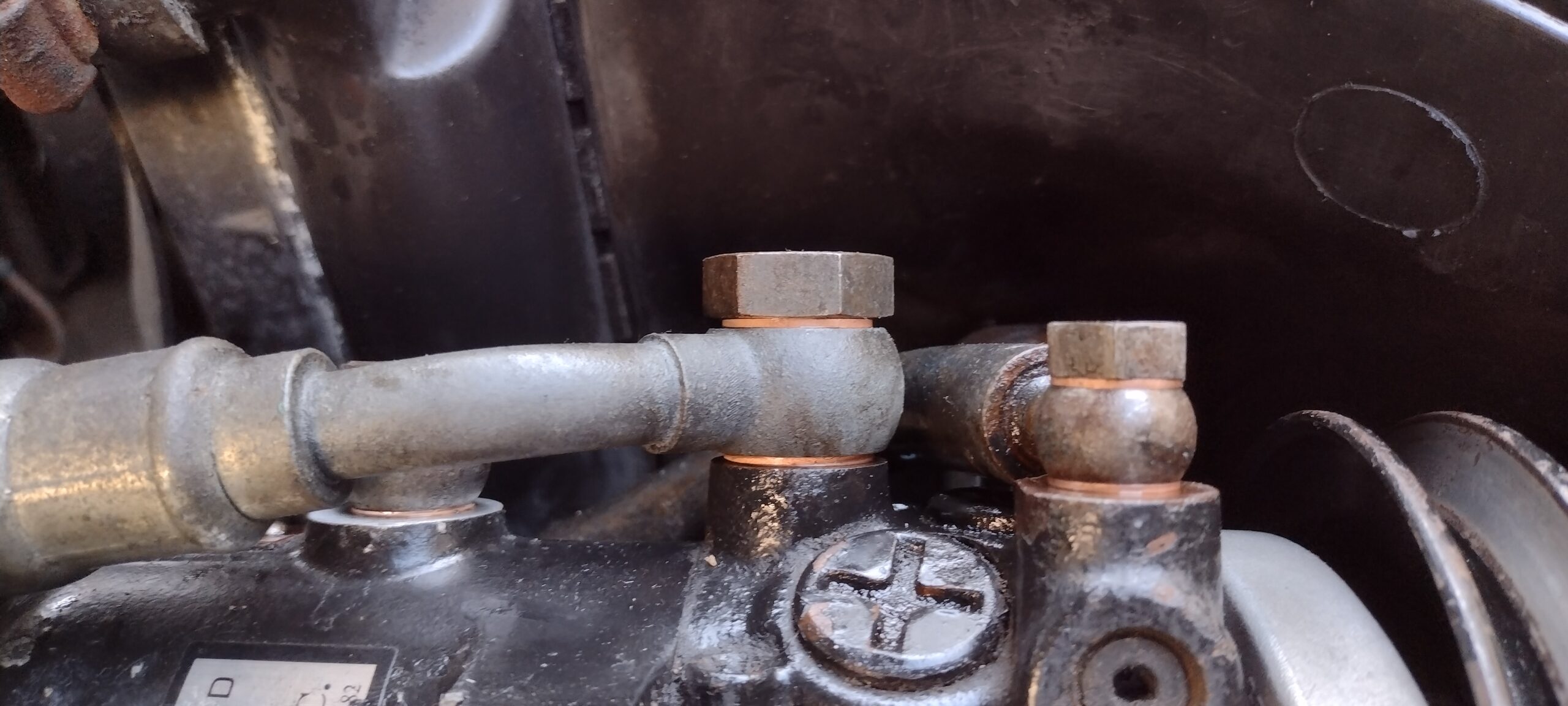

Of course, I needed a new set of crush washers for the pump end of the hoses. Two pressure lines, one return line for a total of 6 washers. I went back to the parts diagrams to get part numbers. I was able to cross reference those numbers and found sizes — but no listings for most of them. Then remembering back again to the box of washers we used to have at the AutoParts store, I went to Amazon and found my own box of 300 crush washers in assorted sizes for $15. Done and Done. I now have a lifetime supply of copper crush washers.

In the meantime, I pulled the strainer from the reservoir and found it full of metal shavings from the old pump and did my best to get it all cleaned out. I’m sure there’s an unfortunate amount of metal in the brake booster and the steering rack still, but I don’t have a good way to flush it all out, so it all went back together. I filled the system with fluid, ran the pump by hand for some initial circulation, saw no drips, put the belt on and then, the moment of truth.

I started the car. The fluid level dropped. I topped it up. The pump turned and was quiet. I had to pump the brake pedal a bunch to bleed out the hydraulic brake booster and of course spun the steering wheel back and forth a number of times. I topped up the reservoir again. The pump kept turning and remained quiet!

There is the smallest of a small fluid weep at the main pressure fitting on the pump, the copper washers are just a little harder than the OEM zinc washers. The Banjo bolt calls for 40ft-lbs of torque, I put 45 on it. As the bolts are NLA, I just need to source some softer washers. But we had brakes and steering now! One step closer to being on the road!