I figured the work on the brake system should be fairly straight forward. A few hard lines to replace, rubber hoses at each corner and voila, we should have a stopping car. Sadly, this adventure in braking ended up not being nearly so smooth.

I started in the right rear, a good place to start as it’s the furthest from the master cylinder and also the corner that was completely missing a brake line. Disassembly was relatively straight forward, I decided to replace everything rear of the junction block forward of the rear left wheel as it was all rather crusty. I ran to the local auto parts store and attempted to purchase some new hard lines as well as the rubber brake hoses for the car. It was at this point a couple facts about this car really hit home.

1) They didn’t make a ton of these — Which means there’s not a lot of part houses making parts for them.

2) It’s a 35 year old car, which compounds the first problem. This actually used to matter less. Back in the 90’s when I worked in a parts store, we literally could get damn near anything for any car next day, maybe 2. There was a large network of independent distributors which carried parts from a endless list of aftermarket parts companies.

It turns out that the aftermarket parts industry has changed DRAMATICALLY in the last 20 years. We’ve gone from a vast network of independent/semi-independent parts suppliers to big consolidated monoliths such as the O’Reilys and AutoZones of the world. These guys own the retail outlets and the intermediate warehouses and if it’s not in the catalog, you can’t get it.

Thankfully, places like RockAuto.com and a multitude of specialty parts houses still exist out there; however; that meant I was waiting a week plus for my “I don’t even have a listing on those!” brake hoses.

In the interim, we got some hard lines and double flare tool, and Lisa crafted some beautiful new lines to match the old ones..or a best guess of what was left of them.

You might think that’s all there is to this tale — but you’d be wrong. Before I got too far into it, I decided to see if I could crack the bleeders loose on the rear calipers for when the system went back together. Of course, they wouldn’t budge. After hours of soaking, heating and hammering at them, the inevitable happened, and I snapped the end of the bleeder off in the caliper.

I dutifully went back to my local parts houses and inquired. Much like with the hoses, some didn’t have a listing, others told me $150 each, we can get them in two weeks, with $15 shipping. This simply wouldn’t do.

So I did what any person who’s frustrated at delays and wants to save a couple hundred bucks does — I bought a new set of bleeders for $5 and made a plan involving drill bit and thread taps.

As it turns out, carefully drilling out the old bleeders, stepping up the bit size until just the barest bit of metal remained in the old threads and subsequently chasing the threads with a tap, was quicker and easier than the hours I’d spent soaking, heating and hammering the old bleeders trying to get them out. Something to keep in mind for the future.

Drilled:

Tapping:

New bleeders installed:

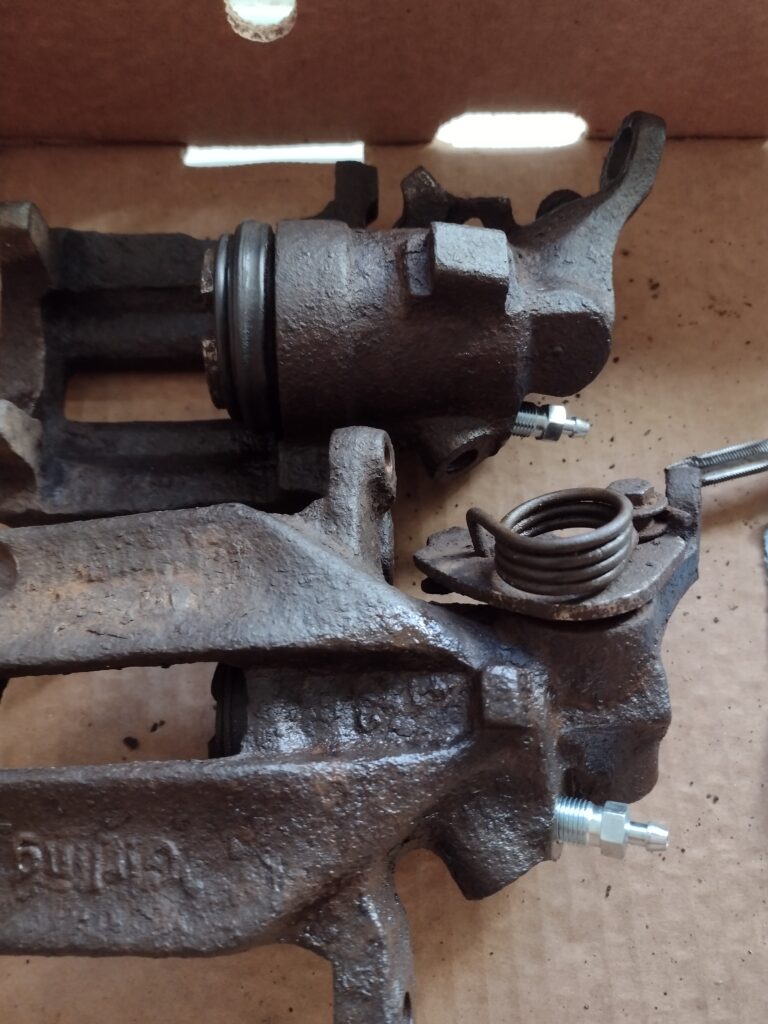

Eventually the rear hoses came in and I laid everything out, ready to go back in, old stuff above, new below. From left to right in the image below we have, left rear caliper, brake hose, line to the junction block, then the other line from the junction block into questionably named Retardation Sensitive Brake Pressure Regulator (The rusty cylinder there, more on this in a moment), the missing line, right hose, right rear caliper. Please note Lisa’s beautiful craftsman ship on the new lines on the bottom…they’re were straight as arrow when she started!

The purpose of this Brake Pressure Regulator is well covered in this instructional video:

If you can’t be bothered to watch the totally 80s-tastic video, basically, there’s check valve in there, under hard cornering, a little ball blocks the flow of brake fluid, there by reducing pressure the caliper and preventing inner wheel lockup during hard cornering and braking as you might encounter in an emergency move.

This device is especially critical in a car such as this with it’s completely ridiculous 62/38 Front/rear weight distribution. This is of course to do the giant cast iron inline 5 cylinder engine hanging out completely forward of the front axle (here’s an opportunity to give your children an object lesson in leverage) — a mechanical design language for Audi that continues into the modern era.

But I digress. Everything went back together easily enough and there was only a minor mishap when bleeding the system out — The LR hose wasn’t quite tight enough — I put the pressure bleeder on the reservoir…and wondered why I wasn’t getting much out the bleeder on the right rear…until I looked across and saw the steady stream of brake fluid pouring from the other side of the car…oh well.

Unfortunately, it was at this time I also noted that one of the e-brake cables was seized up. But that’s for next time along with swapping out the front brake hoses.